We are living in a time of converging crises. Rents and property values are soaring past the stagnant wages of the labor market, leaving many individuals and families unable to obtain housing and causing immense psychological and physical stress, geographic dislocation and unhoused conditions. Climate change, with its documented public health effects, is creating more frequent wildfires and extreme weather events, exacerbating pre-existing health and resource inequalities. Healthy, energy efficient, and affordable housing that contributes to climate change mitigation is key to creating individual, community and planetary resilience, yet it is scarce in both rural and urban areas of our state and beyond. The Institute for Health in the Built Environment is collaborating with the disciplines of architecture, landscape architecture, law, and business together with industry, municipalities and the TallWood Design Institute to develop and propose solutions to these issues through a systematic approach.

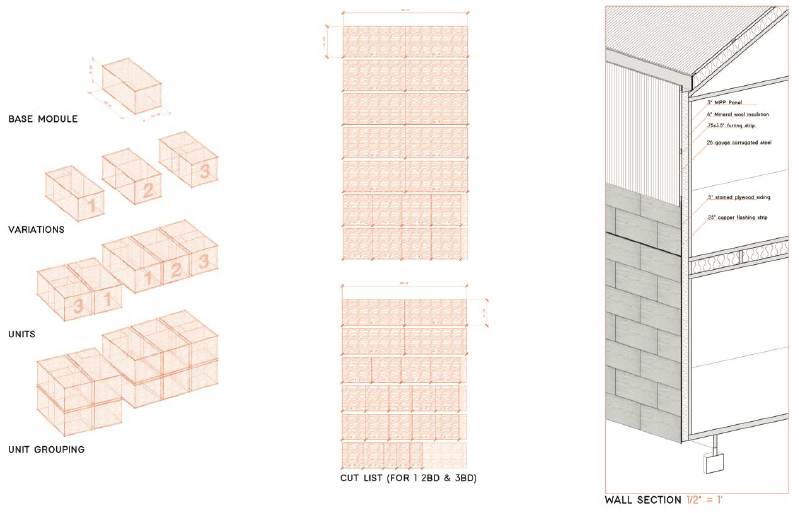

Student work by Flynn Casey

One proposed solution to simultaneously address housing affordability, climate change and health is through the use of panelized wood products. Mass timber panels are created through the composite action of smaller dimensional lumber layered in alternating directions, such as cross-laminated timber (CLT), or through layers of wood veneer adhered with alternating direction, such as mass plywood panels (MPP). Both products are created primarily from wood, which is a renewable resource with the ability to sequester carbon from the atmosphere. While CLT has been available in Europe for several decades and is now gaining North American market share as a structural material, its use has been mostly directed to commercial buildings. MPP is a new product produced by Freres Lumber of Lyons, Oregon and shows great promise for residential building applications due to its ability to be produced in thinner sections than currently available CLT, thereby using less wood fiber and lowering material cost. Since harvested trees are peeled rather than sawn, MPP can use very small diameter trees (down to 5 inches), creating a market for trees harvested from healthy forest initiatives, which have climate, wildfire and rural economic co-benefits.

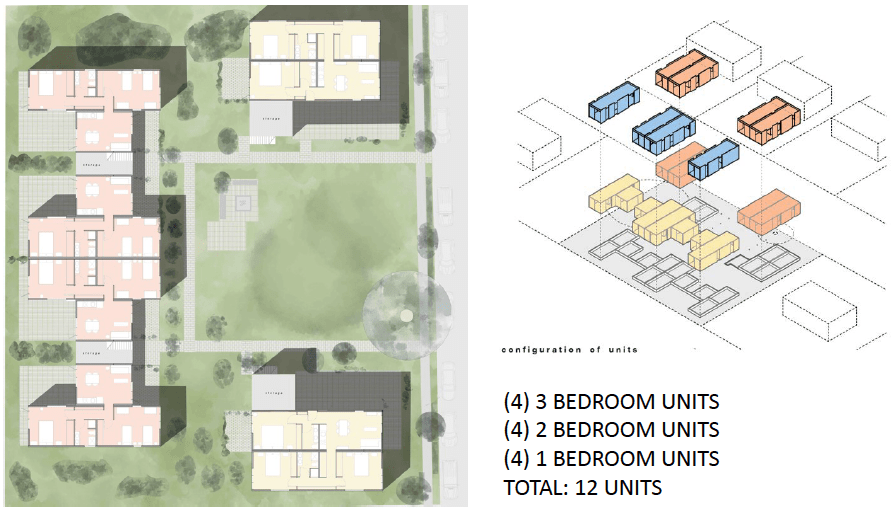

Student work by Flynn Casey

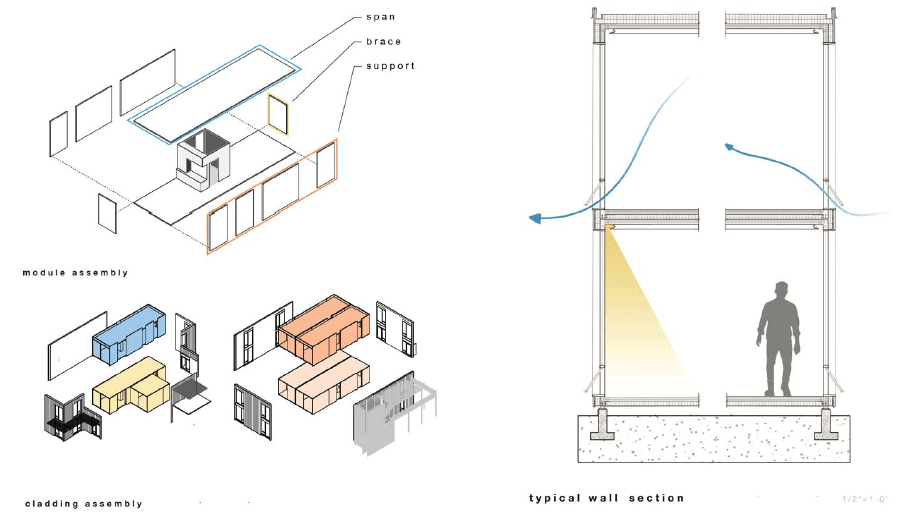

Student work by Flynn Casey

In addition to the climate and rural economic benefits, mass timber products have other distinct advantages over traditional stick frame construction. MPP can be produced in a variety of lengths and widths (12’ x 48’ as of this writing), which can be fabricated into modular housing units through automated digital workflows at an offsite centralized location to reduce construction time. Furthermore, the material can be rabbeted to integrate customized insulated glazing units (IGU), optimized for efficient material usage, and left exposed as a beautiful interior finish, thereby requiring less material and labor.

Judith Sheine, Professor in the Department of Architecture at the University of Oregon and Director of Design for the TallWood Design Institute, is an award-winning architect who has been developing modular design concepts using mass timber panelized digital manufacturing in affordable housing. Sheine believes that “mass timber can enhance environmental stewardship, provide much-needed jobs in Oregon’s rural communities and, quite possibly, provide high-quality, affordable housing through digital fabrication and off-site construction.” This past winter term, Professor Sheine, together with structural engineering consultant, Mikhail Gershfeld, Professor in the Civil Engineering Department at California State Polytechnic University, Pomona taught a design studio that challenged students to use the new material in creative ways to develop workforce housing at a rural site in Stayton, Oregon and an urban site in Milwaukie, Oregon. The Milwaukie site was recently part of a Metro-funded cottage-cluster feasibility study that sought to further address affordability, health and climate by creating denser, walkable neighborhoods closer to the urban core. At the outset of the studio, the students toured the Freres Lumber MPP plant, both Stayton and Milwaukie sites, and met with City of Milwaukie Planning Director, Denny Egner, Assistant Planner, Mary Heberling, Climate Action and Sustainability Director, Natalie Rogers and Cascadia Partners, Garlynn Woodsong, as they began to conceptualize their projects.

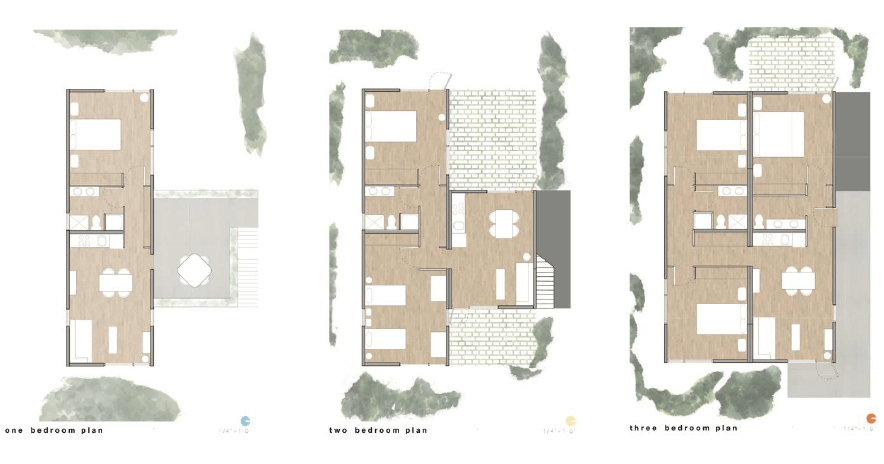

While this work will be ongoing, the results of the winter studio revealed the ability to develop elegant design solutions for a single-family zoned lot in Milwaukie that increased density to 12 units, while maintaining open shared outdoor space, individual privacy and existing neighborhood scale and context. Providence St. Joseph Health, the immediate neighbor to the west of the Milwaukie site, has organizational goals to be carbon negative by 2030 and a broader mission to address health not only through medical treatment but also through the non-medical determinants created by better designed and accessible built environments. Therefore, Providence St. Joseph Health has taken an active role as a member on the Milwaukie cottage-cluster advisory committee and in the outcome of the studio findings. University of Oregon alumna and Providence St. Joseph Health Standards and Design Director, Erin Couch, AIA, traveled to Eugene to attend the final studio review and

Student work by Matthew Weldon

Student work by Matthew Weldon